FROM LIVING TO METAL ?

The lost wax technique is one of my favorite techniques. It is a process in which molten metal replaces, by melting it, a wax model placed in a mold. This method has been known at least since the 4th millennium BC. J.C. in jewelry and it is fascinating. The advantage of this technique is to cast complex parts in one piece (without welding) with great precision in details.

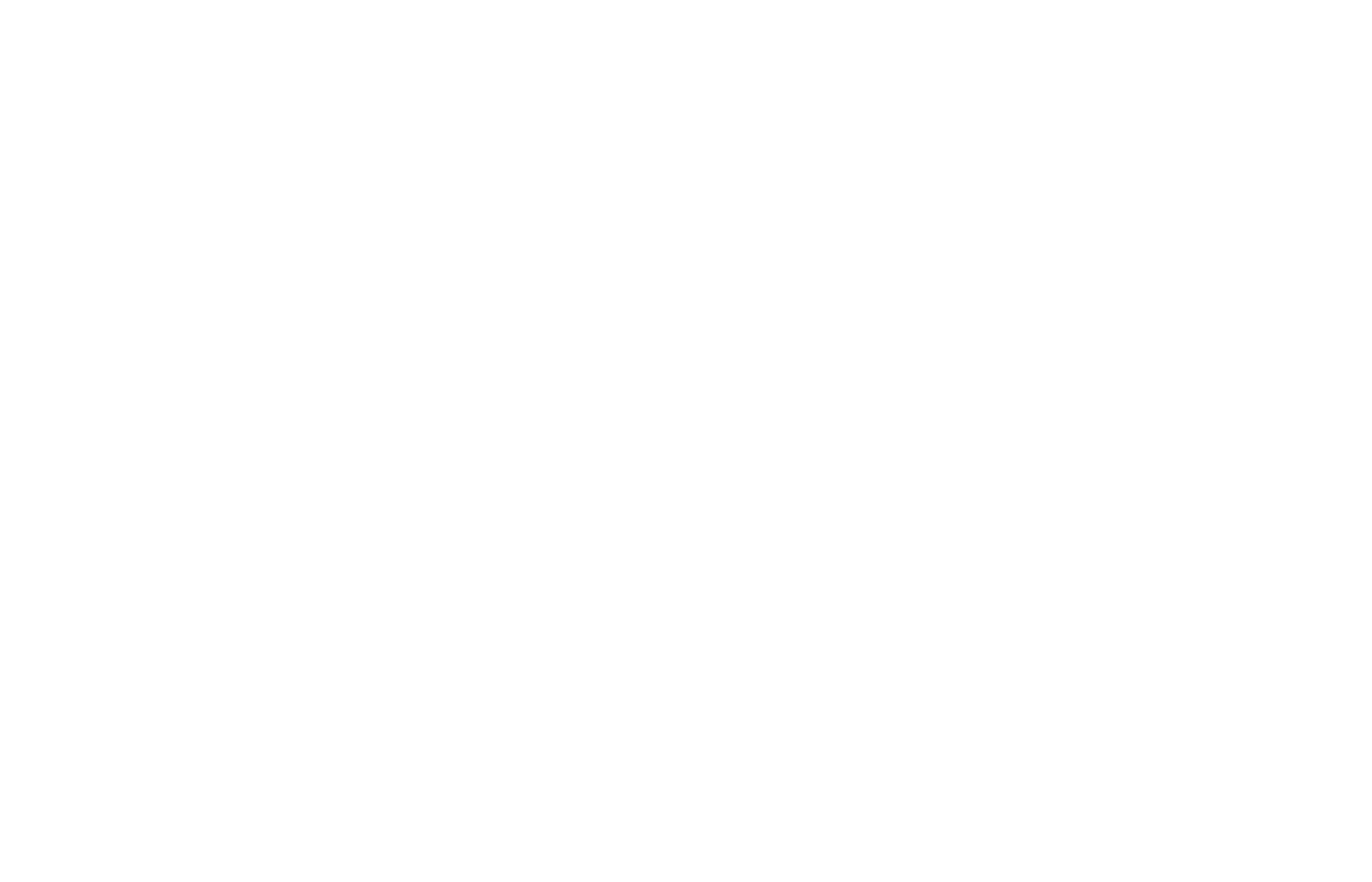

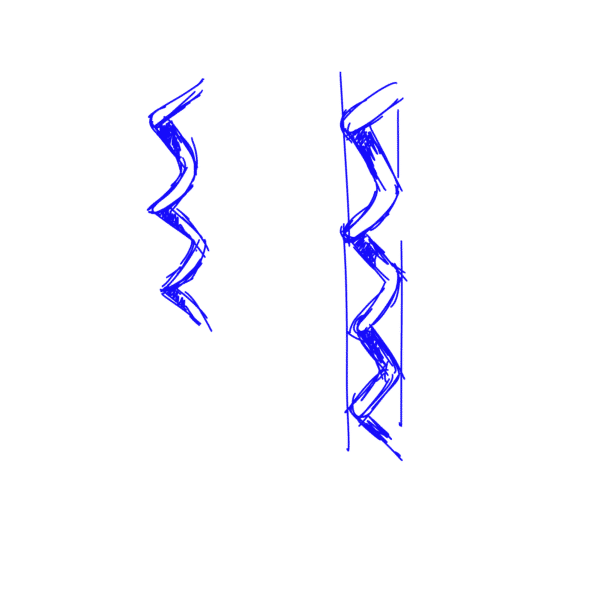

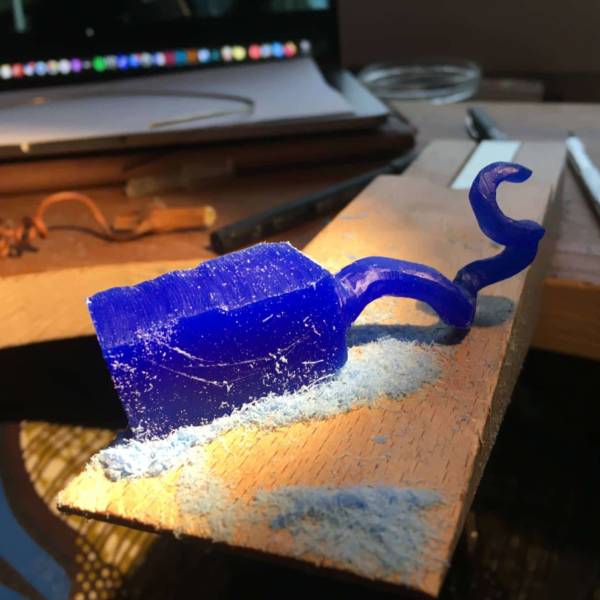

By letting myself be inspired by the vegetal shapes of the vine, I materialized my project on paper and then attacked a piece of still raw wax to create the volume of the desired shape. It took a long time for my brain to rediscover the mechanics of the transition from 2 to 3D that I had already experienced during my visual arts studies. It is necessary to anticipate the gouge strokes to remove the material little by little and thus reveal the desired shapes. Once the model is finished, either take the sculpted wax to a foundry, or equip yourself in your workshop, but the cost is high. My goal is to be able to make my lost wax parts independently one day, but for the moment I use the equipment of a service provider who allows me to make my parts

You can follow the different steps in the photos and view the necessary equipment. After making the model, you need a rubber mold, then inject liquid wax under pressure into the mold. For assembly, the waxes are then placed around a heated rod, to form a casting shaft. The wax tree is placed in a metal cylinder filled with a plaster mixture and then placed in an oven to be fired. The wax tree will melt and flow into it, leaving only the imprint of the objects. Placed upside down, the molten metal is poured into the cylinder and the metal will occupy exactly the place of the wax. Finally, we immerse the hot cylinder in cold water so that the plaster disintegrates and the metal shaft can be recovered, and we proceed to deburring to remove the casting rods.

Pouring tendrils of already lignified vines, often with rough contours, allowed me to create a ring whose finish is deliberately rough, reminiscent of the roughness of branches, but also the force exerted by a tendril to lift the plant towards the light. And also a necklace associating the raw material of part of a branch and a tendril picked from my plot of Pinot Noir with a poured tendril. Both pieces are made of solid 925 silver