Description

This unique model is no longer available but it can be made to order.

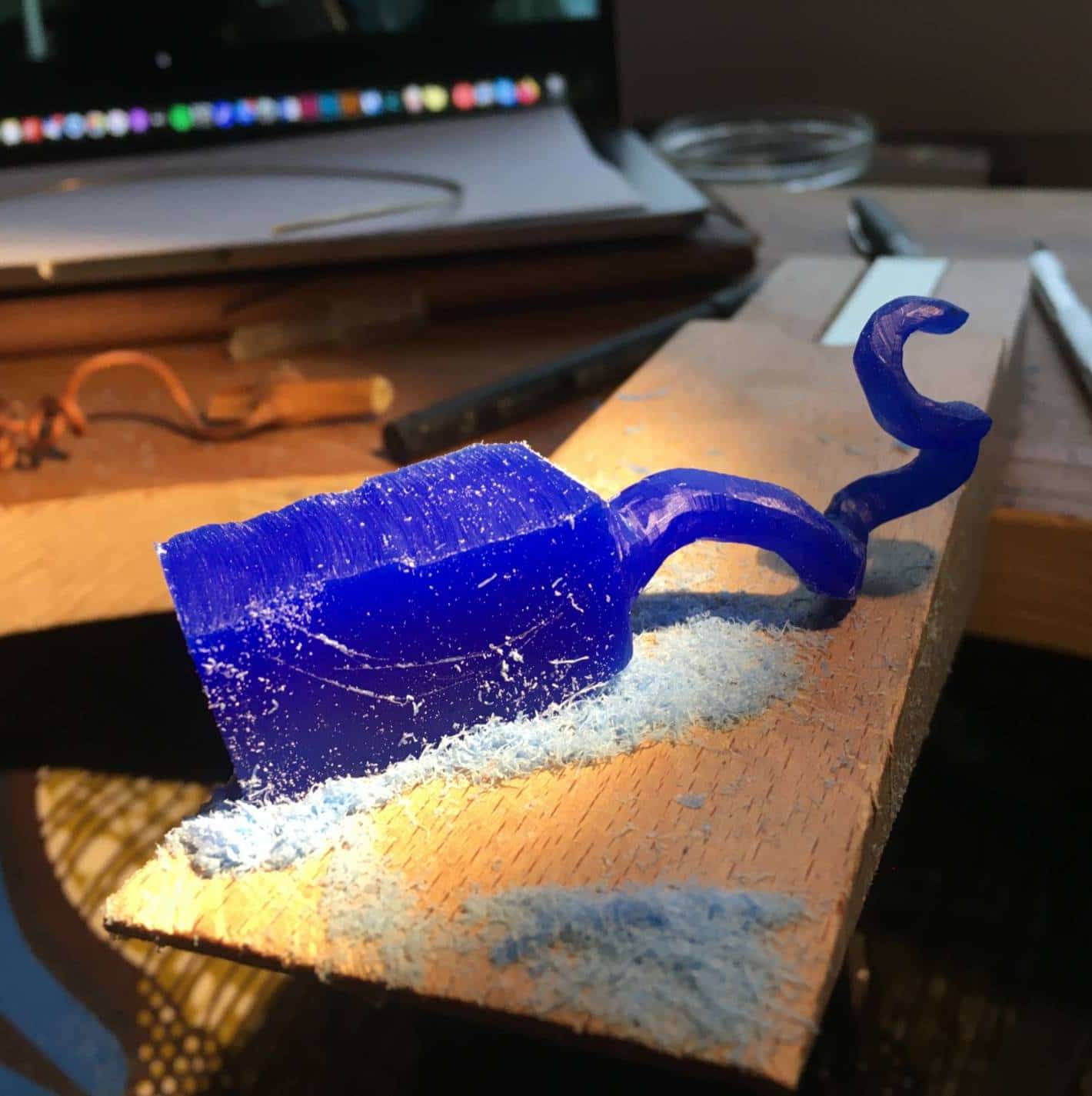

The necklace consists of a silver thread on which two pendants are hanging, the first is in silver 925 and was made using the lost wax casting technique, when the second, it’s a tendril in lignified wood that I harvested after many hours of research in the vineyards to find the right one !

What is lignified wood?

It is a transformation made over time on parts of a vascularized plant that are then transformed into wood; it is the result of the fixation of the lignin between the cells but also inside them.

A lignified plant is therefore more rigid and more solid.

Each model is unique.

The jewel is delivered to your home in a kraft box wrapped in precious paper and the price includes packaging and shipping.